Minis are one of the most popular cars on the road today. Though they are small in size, they pack a big punch when it comes to style and performance. But what exactly is it that makes these cars so beloved? One key reason is their affordability. Minis are very affordable, making them a great choice for budget-minded consumers. Another reason for their popularity is their fuel efficiency. Minis get great gas mileage, which helps to keep operating costs low. Finally, Minis are simply fun to drive. They handle well and are easy to maneuver, making them a joy to take out on the open road. Whether you’re looking for an economical commuter car or a stylish weekend cruiser, a Mini is sure to put a smile on your face.

While the Mini is a reliable car, like any vehicle, it can experience clutch assembly failure. If you experience clutch problems, it is important to have the car inspected by a qualified mechanic to determine the cause of the problem and make the necessary repairs.

What is a clutch assembly?

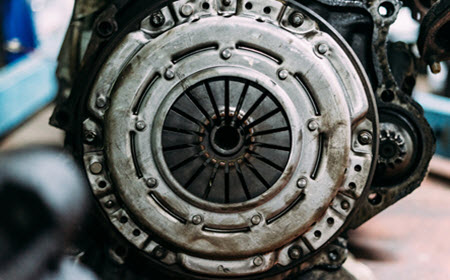

A clutch assembly is a collection of parts that work together to engage and disengage the engine from the transmission. The clutch assembly is located between the engine and the transmission, and it consists of a flywheel, a pressure plate, a release bearing, and a clutch cable. When the engine is running, the flywheel spins along with the crankshaft. The pressure plate is mounted on the flywheel and has a series of springs that apply pressure to a set of friction discs. The friction discs are mounted on the input shaft of the transmission. The release bearing is mounted on the clutch fork, and it presses against the pressure plate to disengage the clutch.

When the clutch pedal is pressed, the release bearing moves away from the pressure plate, allowing the springs to push the friction discs against the flywheel. This connection allows power to be transferred from the engine to the transmission. When the pedal is released, the pressure plate moves back into place and engages the friction discs, preventing power from flowing to the transmission. This is what allows a vehicle to be shifted into different gears. Without a clutch assembly, a vehicle would not be able to change gears and would be stuck in one gear.

What causes clutch assembly failure?

Over time, clutch assemblies can experience wear and tear that can lead to failure. One of the most common causes of clutch assembly failure is a leak in the hydraulic system. When fluid leaks from the system, it can no longer build up enough pressure to engage the clutch. Another common cause of failure is a worn or damaged release bearing. This bearing is responsible for disengaging the clutch, and if it is damaged, it can cause the clutch to slip or chatter.

In some cases, a failed clutch assembly may also be caused by a problem with the flywheel or pressure plate. If these components are warped or damaged, they may not be able to properly engage or disengage the engine from the transmission.

Prevent Clutch Assembly Failure

There are several things that you can do to help prevent clutch assembly failure. First, make sure that the clutch is properly lubricated. This will help to reduce friction and wear. Second, avoid riding the clutch pedal. This can put unnecessary stress on the assembly and cause it to fail prematurely. Finally, have the clutch inspected on a regular basis by a qualified mechanic. By following these simple steps, you can help to keep your clutch assembly in good working order for many years to come.

Come to Euroservice Automotive For Your Clutch Assembly Needs

If you live in or around Bristow, Gainesville,  Haymarket, Manassas, or Warreton, VA, Euroservice Automotive is here to help you get back on the road with a fully functioning clutch assembly. We specialize in European vehicles, so you can always rest assured that your Mini is in the hands of the experts. If you suspect your clutch assembly is failing or could use some general maintenance, call or stop by today to learn more about how we can help.

Haymarket, Manassas, or Warreton, VA, Euroservice Automotive is here to help you get back on the road with a fully functioning clutch assembly. We specialize in European vehicles, so you can always rest assured that your Mini is in the hands of the experts. If you suspect your clutch assembly is failing or could use some general maintenance, call or stop by today to learn more about how we can help.

6583 Merchant Place Suite 304,

6583 Merchant Place Suite 304,